Multi Jet Fusion is an industrial 3D printing process that produces functional nylon prototypes and end-use production parts in as fast as 1 day. Final parts exhibit quality surface finishes, fine feature resolution, and more consistent mechanical properties when compared to processes like selective laser sintering.

How Does Multi Jet Fusion Work?

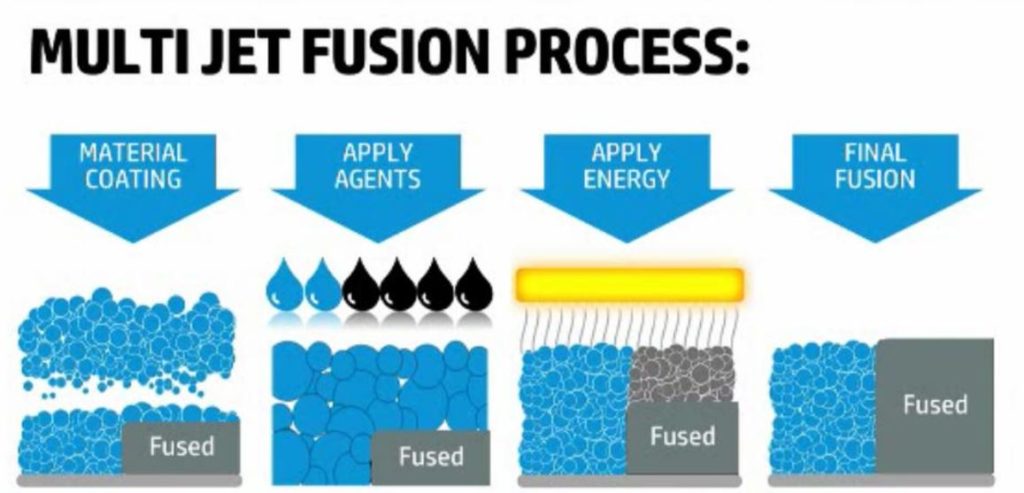

Multi Jet Fusion uses an inkjet array to selectively apply fusing and detailing agents across a bed of nylon powder, which are then fused by heating elements into a solid layer. After each layer, the powder is distributed on top of the bed and the process repeats until the part is complete.

When the build finishes, the entire powder bed with the encapsulated parts is moved to a processing station where a majority of the loose powder is removed by an integrated vacuum. Parts are then bead blasted to remove any of the remaining residual powder before ultimately reaching the finishing department where they are dyed black to improve cosmetic appearance.

Common Applications

parts requiring consistent isotropic mechanical properties

functional prototypes and end-use parts

complex and organic geometries with fine features

MJF PA12

No matter how complex your designs, polyamide is a great and versatile choice. The self-supporting powder needs no support structure and works equally well for fully functional prototypes or end-use parts. The PA 12 material used by Multi Jet Fusion technology has a very fine grain, resulting in parts with higher density and lower porosity than parts produced with Laser Sintering. That feature also makes PA 12 for MJF the ideal choice when you need more detailed surface resolution or thinner walls than are possible with Laser Sintering. Think crisp textures, embossing, and engraving, or labels.